R+D+I

"The team combines perfectly speed in the development of solutions for the customer with the study of new materials, new processes…"

ARTECA has an R&D&i team made up of 9 highly qualified members. The means of production and in house tests enable us to give a swift response to our customer’s problems.

Laboratory

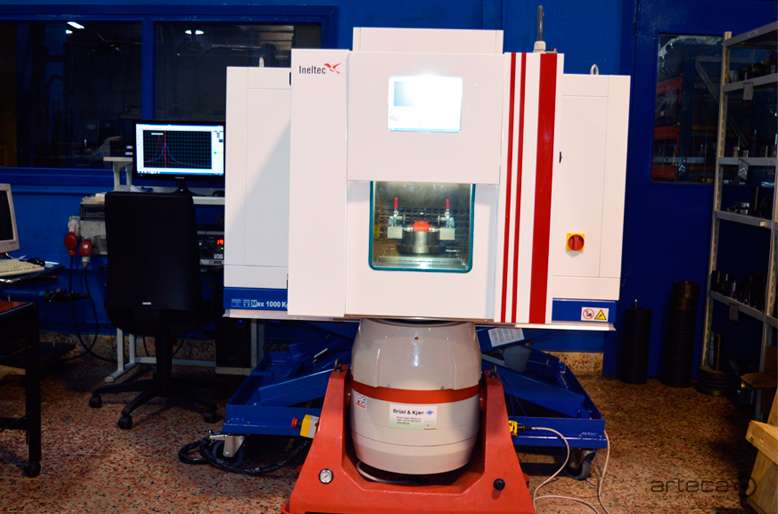

We have a fully equipped multidisciplinary laboratory. We evaluate materials, carry out chemical process controls and all types of tests on parts: static testing, dynamic testing, NVH tests, fatigue, ageing…

The New climatic chamber enables us to do most of these tests at temperatures of between -45º and 200ºC.

Development

Development is a key element at ARTECA. The complete IN HOUSE realisation of the phase of prototypes enables us to offer the customer a solution to whatever problem may arise in a short period of time

Apart from the tailor made development of solutions for our customers, the team is responsible for the development of new applications, the introduction of new materials and the optimisation of the production process.

-

A team of 9 people for automotive development

-

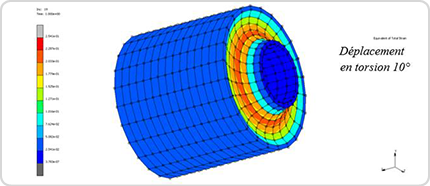

Equipped for analysis with FEA and with tools developed by ARTECA

-

Complete materials, chemicals, mechanics and NVH laboratory

Materials

NOTICE: Access the web from a desktop computer to display the content of this tab.

| Mechanical property | NR | IR | BR | SBR | NBR | IIR | EPDM | CR | CSM | FPM | PTR | PU | VMQ | FVMQ | ACM | CO/ECO |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Traction (with reinforcing filler) |

6 | 5 | 3 | 5 | 5 | 4 | 4 | 5 | 5 | 4 | 3 | 6 | 4 | 4 | 4 | 4 |

| Tearing | 5 | 5 | 2 | 4 | 4 | 4 | 4 | 5 | 2 | 2 | 3 | 6 | 1 | 1 | 4 | 3 |

| Abrasion | 5 | 5 | 6 | 4 | 5 | 5 | 4 | 4 | 5 | 2 | 2 | 6 | 1 | 1 | 3 | 3 |

| Compression Set (23ºC) | 5 | 5 | 4 | 4 | 5 | 3 | 4 | 4 | 3 | 3 | 3 | 4 | 5 | 5 | 4 | 5 |

| Heat resistance | 3 | 3 | 4 | 4 | 4 | 4 | 5 | 4 | 5 | 6 | 3 | 3 | 6 | 6 | 5 | 5 |

| Cold resistance | 5 | 5 | 5 | 4 | 4 | 5 | 5 | 4 | 3 | 6 | 3 | 3 | 6 | 6 | 3 | 4 |

| Ozone resistance | 2 | 2 | 2 | 2 | 2 | 5 | 6 | 5 | 6 | 6 | 6 | 6 | 6 | 6 | 6 | 6 |

| Adhesion to metals | 6 | 6 | 5 | 6 | 6 | 4 | 4 | 6 | 5 | 4 | 4 | 6 | 5 | 5 | 5 | 3 |

| 6 | Excellent | 5 | Very good | 4 | Good | 3 | Regular | 2 | Bad | 1 | Very bad |

| Symbol | Common name | Formula | Trade Marks |

|---|---|---|---|

| NR | Natural rubber | Natural polyisoprene | - |

| IR | Isoprene | Synthetic polyisoprene | - |

| BR | Butadiene | Polybutadiene | Buna |

| SBR | Butadiene-Styrene | Styrene and butadiene copolymer | - |

| NBR | Nitrile | Acrylonitrile and butadiene copolymers | Perbunan N |

| IIR | Butyl | Isoprene and isobutylene copolymers | - |

| EPDM | - | Terpolymer of ethylene, propylene and a diene | - |

| CR | Chloroprene | Polychloroprene | Baypren |

| CSM | - | Chlorosulphonated polyethylene | - |

| FPM | Fluorocarbonaceous | Rubber with fluorinated alkyl and alkoxy side groups | Vitton |

| PTR | Polysulphide | Polysulphide | - |

| PU | Polyurethane | Polyester urethane or polyether urethane | Vulkollan, Desmopan, Adiprene, Urepan |

| VMQ | Silicone | Polysiloxane with methyl and vinyl side groups | - |

| FVMQ | Fluorinated silicone | VMQ with trifluoropropyl side groups | - |

| ACM | Polyacrylic | Ethyl acrylate copolymer | Vamac |

| CO/ECO | Epychlorhydrine Epychlorhydrine copolymer |

Epychlorhydrine homopolymer / Epychlorhydrine and ethylene oxide copolymer | - |